Technology

We offer three standard core options, RibCore,

Expanded Polystyrene (EPS) Solid Core and Moisture Resistant(MR) Particle Board Solid Core.

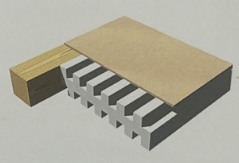

RibCore

Polystyrene RibCore provides a cost effective method of increasing the strength of hollow core doors. RibCore doors have up to 42% glue contact between the core and skin compared to approximately 4% in honeycomb paper core doors. Greater contact between the surface of the core and the door skin leads to a much stronger, flatter, impact resistant door.

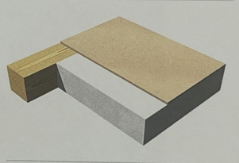

Expanded Polystyrene Solid Core (EPS)

As an alternative to a standard heavy solid particle board core door, Supreme Doors provides the option of the Premium High Density Solid EPS Polystyrene Core. The High Density EPS Polystyrene Solid Core further enhances thermal insulation, as well as providing even greater impact resistance. The EPS core does all this while being cost effective, safer and easier to handle than traditional solid core doors.

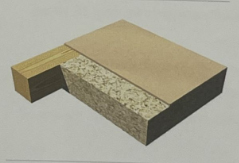

Mousture Resistant (MR) Particle Board Solid Core

For those who require a door with maximum impact resistance we offer the MR Particle Board solid core option. The MR Particle Board Core is more moisture resistant than standard particle board and is the ultimate core option for strength, durability and is the best care option for acoustic insulation.

Architechture

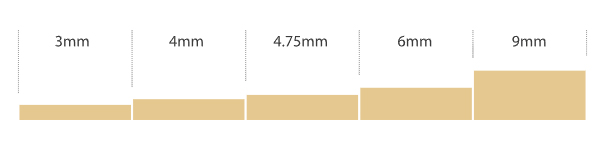

Our Pre Primed skins use an Ultraviolet (UV) primer which is solvent and formaldehyde free, no V.O.C's (Volatile Organic Compounds). This Pre Priming solution is moisture and solvent resistant, also harder and more scratch resistant than standard and cheaper water based door priming solutions.